IIoT-based Shop Floor Management System

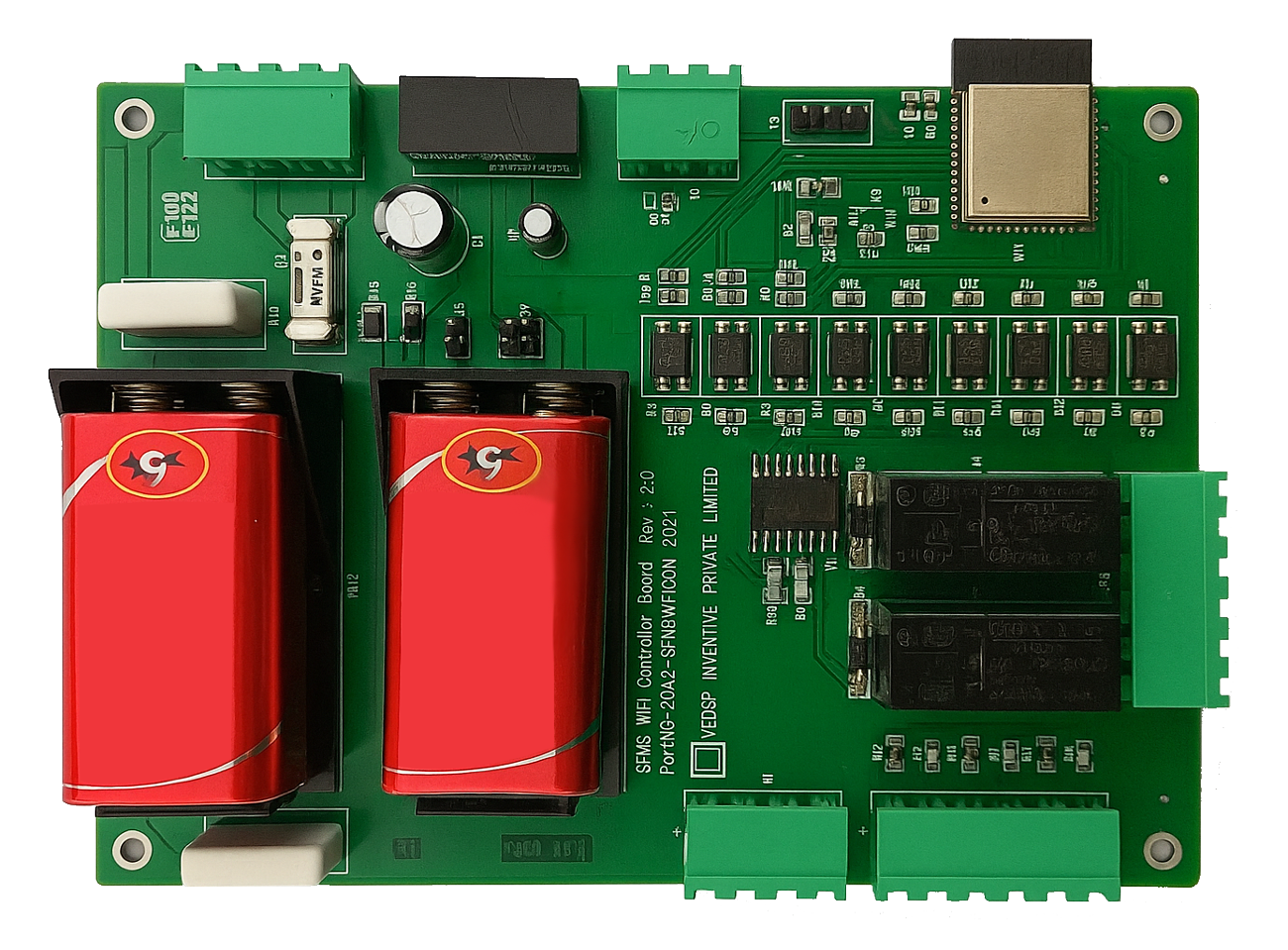

A compact, industrial-grade IoT controller built for shop floor automation and real-time productivity monitoring. With robust Wi-Fi connectivity, 24V DC operation, and battery backup, it ensures uninterrupted performance. The board features 5 digital outputs, 2 opto-isolated inputs, and an analog input-perfect for machine control, sensor integration, and data acquisition. Built on the powerful ESP32/ESP8266 microcontroller, it supports MQTT and HTTP protocols for seamless cloud communication. Ideal for smart factories, equipment monitoring, and remote diagnostics. Boost efficiency, traceability, and control—right from the floor to the cloud. Reliable. Scalable. Industry-ready.

Solving Shop Floor Challenges

IIoT – Built to Fit Your Existing Infrastructure

1. Integration into Existing Machines

🔧 Problem: Most IoT systems require replacing existing hardware.

💡 Our Solution: Our system works with your existing machines, offering a scalable, low-cost upgrade without disruptions.

2. Manual Errors & Missed Inspections

🔧 Problem: Manual recording leads to mistakes and skipped checks.

💡 Our Solution: Automatically trigger Patrol, First-Off, and Last-Off inspections with built-in specification checks and alerts.

3. Downtime & Root Cause Tracking

🔧 Problem: Machine downtime goes unrecorded or unexplained.

💡 Our Solution: The system logs every machine stop with reasons, helping analyze and reduce idle time.

4. Centralized Control or Traceability

🔧 Problem: Disconnected systems make it hard to trace job history or quality issues.

💡 Our Solution: Manage job progress, product traceability, and productivity from one central dashboard.

5. Data Loss & No Backup for Audits

🔧 Problem: Production data is not stored or easily retrieved when needed.

💡 Our Solution: Automatic data backup ensures hourly, daily, and monthly production records are safe and audit-ready.

6. Real-Time Visibility

🔧 Problem: Shop floor performance is hard to monitor without live data.

💡 Our Solution: Get real-time machine data with timestamps directly from the SFMS Wi-Fi Controller and monitor it live via our web app.

🔧 Use Cases

Flexible and adaptable — ideal for a wide range of industrial and smart automation scenarios.

Automobile Parts Manufacturing

Monitor machine status, ensure quality control, track production efficiency, and control equipment remotely in automotive component manufacturing.

Smart Waste Bin Controllers

Monitor fill levels and optimize collection schedules in smart cities.

Remote Machine Monitoring

Track machine performance and productivity in real-time from anywhere.

Smart Building Automation

Control and monitor lights, HVAC, and other systems efficiently.

Utility Equipment Status Logging

Log operational data from water pumps, generators, and compressors.

Solar-Powered Sensor Nodes

Deploy low-power sensor networks for remote data collection.

Industrial Control Panels

Enable smart automation in existing industrial equipment setups.

The Software

Software & Webapp Highlights

The SFMS software is a powerful web-based platform designed to work seamlessly with the SFMS WiFi Controller Board. It helps manufacturers monitor, manage, and optimize every aspect of shop floor operations in real time. You can track machines, tools, and client information from a single dashboard. Easily create jobs, assign Job IDs, and monitor every stage of production. The system stores stage-wise specifications, automatically triggering alerts for inspections like Patrol, First-Off, and Last-Off.

Asset Tracking

Real-time tracking of Manage machines, dies, and client info

Auto Machine Control

Stop machine automatically on spec deviation

Job Management

Create jobs with Job IDs and track every manufacturing stage.

Dashboard

Real-time machine performance & Job progress and inspection alerts

Specification & Control Plan

Store stage-wise specs and trigger: 1. Patrol Inspection, 2. First-Off / Last-Off Inspections

Detailed Reports

– Daily Production Report

– Idle Time Analysis

– Material Stock Report

Hardware

Latest Tech for existing system

The SFMS WiFi Controller Board Rev 2.0 is a compact and reliable Industrial IoT (IIoT) controller designed for smart automation, equipment monitoring, and remote control applications. It supports Wi-Fi connectivity and features a robust power system with a 24V DC input and built-in battery backup for uninterrupted operation during power outages. Opto-isolated inputs and a dedicated analog input make it ideal for industrial-grade signal monitoring and control.

Wi-Fi Enabled

Integrated Wi-Fi module (ESP32/ESP8266) for remote access, OTA updates, and cloud communication

Signal Isolation

Built-in optocouplers for safe signal separation and noise immunity

Cloud Ready

Compatible with MQTT, HTTP, or custom REST APIs

Dual Power System

Operates on 24V DC with automatic switch-over to 2× D-cell battery backup during power failure

2 Digital Inputs

Opto-isolated inputs for secure signal interfacing

Energy Efficient

Designed for low-power operation in industrial environments

5 Digital Outputs

Transistor-based or relay-compatible outputs for controlling external devices efficiently.

User Friendly UI

Screw terminal blocks for easy wiring and field deployment

1 Analog Input

For sensors or variable voltage monitoring (e.g., 0–3.3V or 0–5V based on design)

Technical Specifications

Domain-Driven. Industry-Tested.

Software

💻 Software Specifications

🔧 Embedded Programming

- Written in C

- GPIO Interrupts for machine pulse counting

- MQTT Client integration

- Wi-Fi Configuration & OTA updates

📡 Data Pipeline

- Node.js + Python backend

- Bridges MQTT messages to MS SQL Server

- Real-time timestamped machine data

🌐 Web Application

- ASP.NET (C# with ASPX)

- JavaScript for interactive dashboards

- User-friendly interface & alerts

Hardware

🔌 Hardware Specifications

| Parameter | Value / Description |

|---|---|

| Board Version | Rev 2.0 |

| Part Number | 8542-SFMSWIFICON-2021 |

| Primary Power Supply | 24V DC |

| Backup Power | 2× D-cell Eveready batteries (3V total) |

| Microcontroller | ESP32 / ESP8266 |

| Digital Inputs | 2× Opto-isolated Digital Inputs |

| Digital Outputs | 5× Digital Outputs (open-drain or relay-type) |

| Analog Input | 1× Analog Input (e.g., 0–3.3V or 0–5V) |

| Isolation | Optocoupler for signal & power isolation |

| DC-DC Converter | Isolated 24V to 3.3V step-down converter |

| Wi-Fi Connectivity | IEEE 802.11 b/g/n |

| Mounting | PCB with screw-mount holes |

| Dimensions | Approx. 100mm × 80mm (TBD) |